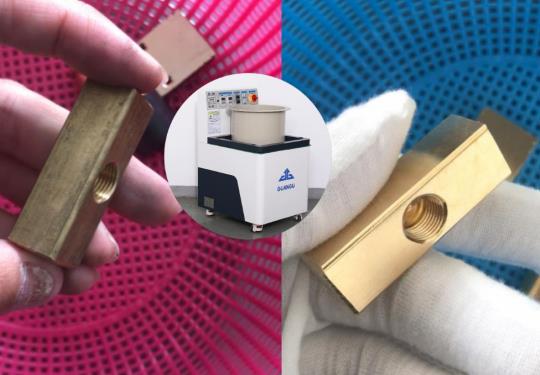

Magnetic tumbling machine is a surface treatment equipment, mainly used for polishing and surface treatment of metal parts. It utilizes a magnetic field to drive abrasive particles to polish the surface of the workpiece to remove oxides, dirt and roughness, and to improve the surface finish and quality of the parts.

The working principle of magnetic tumbling and polishing machine is that the workpiece is put into the magnetic field, and the abrasive particles are driven by the force of magnetic field to produce high-speed friction on the surface of the workpiece, so as to realize the polishing effect. Compared with the traditional sand blasting polishing, electrolytic polishing and other methods, magnetic tumbling polishing has the advantages of environmental protection, safety, efficiency and so on.

Magnetic tumbling machine can be applied to the surface treatment of various metal parts, such as precision bolts, analytical instrument parts, jewelry, metal parts of electronic products, automotive parts, aviation parts, medical equipment and so on. In practical application, magnetic tumbling machine can be adjusted according to the material, shape and surface requirements of different parts to achieve the ideal polishing effect.

Magnetic tumbling machine is a kind of surface treatment equipment, mainly used for polishing and removing oxides, dirt and roughness from the surface of metal parts. The following are some metal parts that can be polished with magnetic tumbling machine:

- Precision bolts: Magnetic tumbling machine can effectively remove the burrs and roughness on the surface of precision bolts, so that they have good smoothness.

- Analytical instrument parts: such as separation columns, reactors, electrodes, etc. These parts require highly precise surface treatment, and magnetic tumbling machine can meet their requirements.

- Jewelry and fashion accessories: Magnetic tumbling machine can be used for polishing gold and silver jewelry, fashion accessories and other metal products to improve their surface brightness.

- Metal parts of electronic products: such as cell phone shells, computer radiators, etc. Magnetic tumbling machine can remove the oxidized layer, dirt and roughness on the surface of these parts to improve the quality of their appearance.

- stationery accessories: such as pen holders, pen holders and other metal products, magnetic tumbling machine can make its surface more smooth and beautiful.

- automobile parts: such as engine parts, transmission system parts, etc., magnetic tumbling machine can be used for deburring, polishing and de-oxidizing.

- Aviation parts: such as aircraft engine parts, aircraft structural parts, etc., magnetic tumbling machine can be applied to these high-precision, high-demand metal parts surface treatment.

- Medical devices: such as orthopedic implants, dental implants, etc. Magnetic tumbling machine can be used for polishing and removing surface roughness to improve its biocompatibility.

In short, magnetic tumbling machine can be applied to the surface treatment of various metal parts to improve their finish, aesthetics and performance. However, in practical application, it is necessary to choose the appropriate polishing parameters and equipment according to the material, shape, requirements and other factors of specific parts.

Wechat

Wechat