Copper heating tube is a kind of heating element made of high-quality copper, with excellent thermal conductivity and corrosion resistance. In many industrial production processes, copper heating tube plays a vital role. As a surface treatment technology, polishing is important for improving the performance and appearance of copper heating tubes. In this paper, we will discuss the performance, polishing process and application of copper heating tube.

First, the performance characteristics of copper heating tube

- Excellent thermal conductivity: copper has a high thermal conductivity, making the copper heating pipe in the heat transfer process has a high thermal efficiency, can quickly transfer heat to the heated object.

- Corrosion resistance: copper heating pipe has good corrosion resistance, can work stably in a variety of media, not easy to rust.

- Good mechanical properties: copper heating pipe has high strength and toughness, can maintain stable work in high temperature, high pressure and other complex environments.

- Easy to process: copper has good processing performance, according to the need to make a variety of shapes and sizes of heating elements.

Second, copper heating tube polishing process

- Mechanical polishing: mechanical polishing is the use of polishing machines, polishing wheels and other tools on the surface of the copper heating tube grinding, friction, in order to achieve the purpose of removing the surface oxidation layer, dirt and burrs. Mechanical polishing is divided into two stages of coarse polishing and fine polishing, coarse polishing is mainly used to remove the surface of the oxide layer and burrs, fine polishing is used to improve the surface finish.

- Chemical polishing: chemical polishing is the use of chemicals on the surface of copper heating tube corrosion, in order to achieve the purpose of removing the oxide layer, dirt and burrs. Chemical polishing has the advantages of fast polishing speed, good finish, but it should be noted that the chemical polishing will produce a certain amount of pollution of the environment, so in practice need to take appropriate measures.

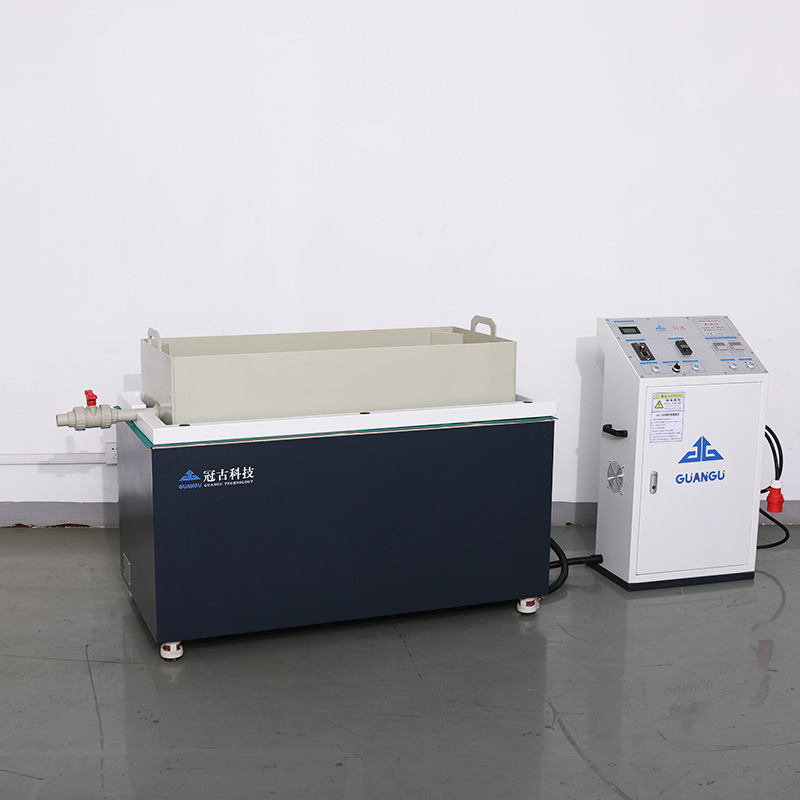

- Electrochemical polishing: electrochemical polishing is through the electrochemical reaction on the surface of copper heating tube polishing. This method has the advantages of fast polishing speed, good finish, environmental protection, but need to be equipped with the corresponding electrochemical equipment.

- Manual polishing: manual polishing is mainly the use of sandpaper, polishing cloth and other tools for manual polishing, suitable for small batch production or polishing requirements are not high occasions.

Third, the application of copper heating tube

- Chemical industry: Copper heater is widely used in chemical industry, such as reactor heating, pipeline heating, tank heating and so on.

- Pharmaceutical field: In the process of pharmaceutical production, copper heating tube can be used for container heating, pipeline heating, etc., to ensure the quality of drugs and production efficiency.

- Food field: Copper heating tubes are also widely used in food processing industry, such as baking equipment, cooking equipment, etc.

- Energy field: Copper heating tube has an important role in the field of solar energy, ground source heat pump and other energy utilization, such as heating medium, heat exchanger and so on.

In short, as an important heating element, the purple copper heating tube plays an important role in many fields. Through the polishing process, the performance and appearance of the purple copper heating tube can be further improved to meet the demand for higher quality. In the future development, copper violet heating tube will continue to optimize the production process, improve product performance, and provide better heating solutions for various industries.

Wechat

Wechat