With the rapid development of science and technology, lithium battery, as an efficient and environmentally friendly new energy source, has become the core power source of various electronic products. Lithium batteries have received widespread attention due to their superior performance, such as high energy density, long cycle life and low self-discharge rate. However, the safety performance of lithium batteries has also become increasingly prominent, especially in the shell material and process. Lithium battery shell polishing technology is of great significance in improving the safety performance of lithium batteries.

First, lithium battery shell polishing technology

Lithium battery shell polishing technology refers to the use of physical or chemical methods of lithium battery shell processing, so that its surface smooth, beautiful, and improve its protective properties. Lithium battery shell polishing technology mainly includes mechanical polishing, chemical polishing and electrochemical polishing.

- Mechanical polishing: grinding, wiping and other mechanical effects on the surface of the lithium battery shell through the abrasive, so that the shell surface to achieve a smooth effect. Mechanical polishing process is simple, low cost, but easy to produce scratches and wear.

- Chemical polishing: the use of chemical solutions on the surface of the lithium battery shell corrosion, so that the surface of the oxidized layer off, so as to achieve a smooth effect. Chemical polishing can obtain a smooth surface, but need to control the concentration of chemical solution, temperature and polishing time, so as not to affect the strength of the shell and protective properties.

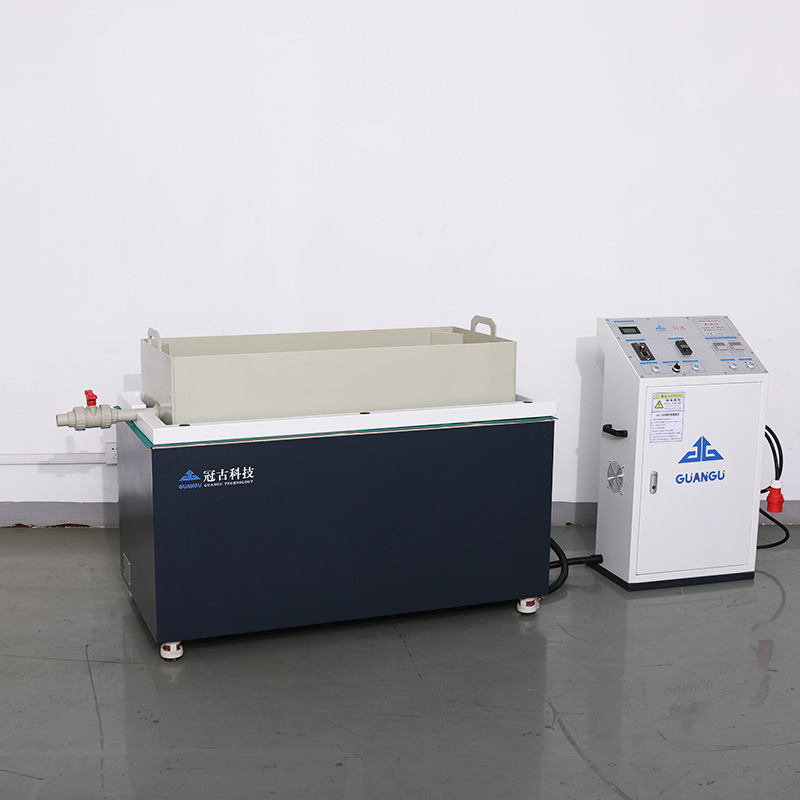

- Electrochemical polishing: through electrochemical reaction on the surface of lithium battery shell processing, so that the surface oxidation layer off, so as to achieve a smooth effect. Electrochemical polishing has a better uniformity and stability, but the equipment cost is higher, and there are certain requirements on water quality and environment.

Second, the challenges and development of lithium battery shell polishing technology

- Improve polishing efficiency: lithium battery shell polishing process, how to improve polishing efficiency, reduce processing time and cost is an urgent problem. Therefore, the study of efficient, energy-saving polishing technology and equipment is of great practical significance.

- Optimize the polishing process: for different materials of lithium battery shell, how to choose the appropriate polishing process and parameters, in order to achieve the best polishing effect and protective properties, is the key to the development of polishing technology.

- Improve the polishing quality: lithium battery shell polishing process, how to ensure the flatness, smoothness and consistency of the polished surface, is to improve the safety performance of lithium battery is an important factor. Therefore, it is crucial to study high-precision, high-stability polishing technology and equipment.

- Environmental protection and sustainable development: the lithium battery shell polishing process produces waste and pollutants have a certain impact on the environment. Therefore, the development of green, environmentally friendly polishing technology and process, to achieve sustainable development, is the future of lithium battery shell polishing technology is an important direction of development.

In short, lithium battery shell polishing technology is important in improving the safety performance of lithium batteries. With the continuous progress of science and technology, lithium battery shell polishing technology will continue to optimize and develop, providing strong support for the development of lithium battery industry.

Wechat

Wechat