Aluminum parts are widely used in manufacturing, home decoration and other fields, however, traditional polishing methods are time-consuming, labor-intensive and costly. How to achieve aluminum polishing to save money? This article will introduce you to a new type of polishing equipment – magnetic polishing machine, and its advantages in the application of aluminum polishing.

First, aluminum polishing overview

Aluminum polishing refers to the physical or chemical methods to remove the surface of the aluminum oxide layer, oil, scratches, etc., so that the surface is smooth, beautiful a processing technology. Traditional aluminum polishing methods mainly include hand polishing, mechanical polishing, chemical polishing and so on. Although these methods can achieve a certain polishing effect, but there are the following shortcomings:

1. low polishing efficiency, time-consuming;

2. high labor intensity, high skill requirements for operators;

3. high cost of polishing, especially chemical polishing, there is a certain degree of pollution of the environment;

4. polishing quality is not stable, easy to defects.

Second, the advantages of magnetic polishing machine

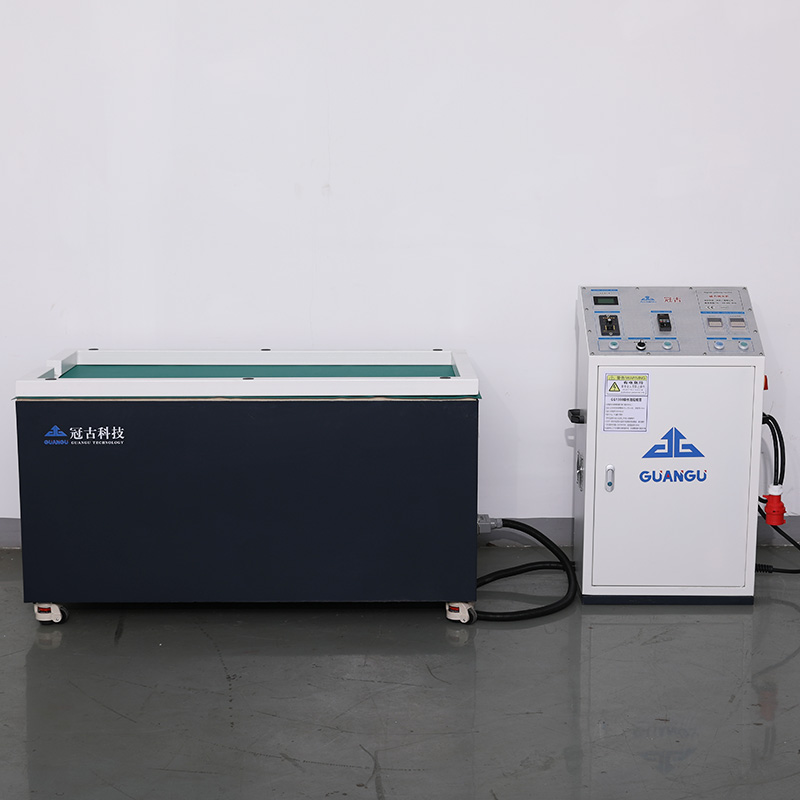

Magnetic polishing machine is a new type of polishing equipment, the use of magnetic field principle, through the magnetic grinding media to polish the workpiece. Compared with traditional polishing methods, magnetic polishing machine has the following advantages:

1. fast polishing speed and high efficiency. Magnetic polishing machine adopts batch processing, can polish several workpieces at a time, greatly reducing the polishing time.

2. Good polishing effect. Magnetic polishing machine adopts magnetic field guidance, the grinding medium can act evenly on the surface of the workpiece, effectively remove the oxide layer, oil, scratches, etc., so that the surface of the workpiece is smooth and flat.

3. Easy operation. Magnetic polishing machine with high degree of automation, the operator only needs to put the workpiece into the equipment, set the parameters, and then start polishing. Reduced labor intensity, lower skill requirements for the operator.

4. Cost saving. Magnetic polishing machine covers a small area, low energy consumption, and the grinding media can be reused, reducing the cost of polishing.

5. Environmental protection and no pollution. Magnetic polishing machine adopts physical polishing principle, no need to use chemicals, no pollution to the environment.

Third, the application of magnetic polishing machine in aluminum polishing

1. aluminum alloy doors and windows: magnetic polishing machine can quickly remove the oxidation layer on the surface of aluminum alloy doors and windows, oil, etc., to improve the aesthetics and service life of the doors and windows.

2. aluminum alloy wheel hub: magnetic polishing machine on the wheel hub polishing, so that its surface is bright as a mirror, to enhance the overall grade of the car.

3. aluminum alloy radiator: magnetic polishing machine can improve the surface finish of the radiator and enhance the heat dissipation effect.

4. aluminum alloy crafts: magnetic polishing machine is suitable for all kinds of aluminum alloy crafts polishing, make it more ornamental value.

Summary: magnetic polishing machine as a new polishing equipment, in the field of aluminum polishing has significant advantages. The use of magnetic polishing machine for aluminum polishing, not only can improve the polishing efficiency, reduce costs, but also to ensure the polishing quality, to achieve environmental protection production. With the continuous progress of technology, magnetic polishing machine will play an important role in more fields.

Wechat

Wechat